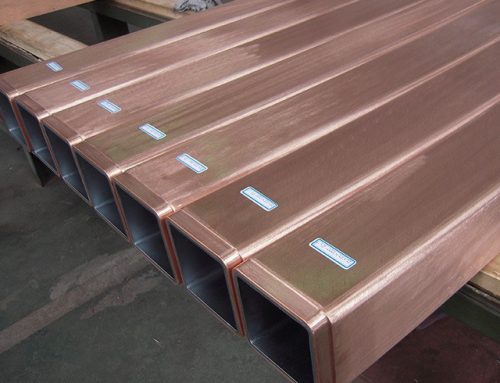

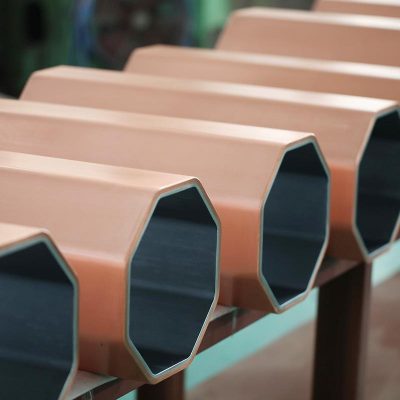

Project Description

We supply all kinds of Copper Mould Tubes of all sizes and dimensions, produced exactly as per the required drawing.

Row Materials

To provide mould tubes with optimal physical and mechanical properties to customers’ specifications, mould tube products are supplied of the following materials

- Cu-DHP: Normally used for mould tubes section size below 180x180mm and round tubes below Dia.150mm.

- Cu-Ag: Normally used for mould tube section size above 180x180mm and round tubes above Dia.150mm.

- Cu-Cr-Zr: Normally used for beam blank mould tubes.

These materials have different levels of hardness and thermal conductivities. We are highly experienced in choosing proper materials to meet the specific demands in heat resistance and thermal conductivities of customers’ applications.

Coating

In order to increase the erosion resistance and service life the casting mould tubes, we always dedicated to research special coatings. The mould tubes can be coated with our different types of internal surface coating:

- Cr

- Ni-Co

- Ni-Fe

- Ni-Co-Cr

The coating thickness recommended by us has been controlled in the best range.

Taper

The Taper of Copper Moulds is of vital importance to performance and life.

We supply Copper Moulds of the best suitable tapers and stronger anti-wearing plating for copper mould tubes and mould plates.

Ranging from Single Taper, Double Taper, Triple Taper to Multiple Taper we supply all variants.

Each mould taper is tested by the computer-operated taper monitor and the taper graph for each mould tube is delivered along with mould tubes.