Founded in 1992

Henan Shengmiao Instrument Co., Ltd. is one of China’s leading supplier of copper mould tubes and plates for the continuous casting industry. With over 20 years of expertise in the metallurgy industry of copper and copper alloys, the company is committed to research & development and providing a range of high-quality, innovative, cost-effective copper mould tube products and solutions.

Being approved by international well-known inspection institutions such as SGS, OMIC, IKA, ISQI, COTECNA, our products have been exported to Europe, Asia, Africa, South America, and Middle Eastern countries, which enjoys a good reputation.

Products

News & Events

Cause Analysis and Improvement Measures of Center Shrinkage of Billet

1. Analysis of the causes of shrinkage The influence of overheating on shrinkage The high degree of superheating of molten steel will make the columnar crystals of the cast slab coarser, and aggravate the [...]

Latest Price Update in the China Copper Market – 14 July 2021

14 July 2021 Update: China Copper Price Chinese Yuan¥ PER TONNE Data valid for 14 July 2021 [wpdatatable id=7 table_view=regular]

Latest Price Update in the China Copper Market – 13 July 2021

13 July 2021 Update: China Copper Price Chinese Yuan¥ PER TONNE Data valid for 13 July 2021 [wpdatatable id=5 table_view=regular]

Latest Price Update in the China Copper Market – 12 July 2021

12 July 2021 Update: China Copper Price Chinese Yuan¥ PER TONNE Data valid for 12 July 2021 [wpdatatable id=5 table_view=regular]

Crystallization copper mould tubes have good and thermal conductivity but are easily oxidized in air.

The use of antioxidants, also known as copper antioxidants, improves the discoloration and antioxidant resistance of the crystallizer copper tube. Form passivation film on its surface to prevent surface dark and improve corrosion resistance, discoloration, and oxidation resistance. And does not affect the welding performance. In particular, crystallizer copper tubes were used for passivation after grinding. The number of antioxidants used in the raw fluid can be used directly. Antiantioxidant protector is the last antioxidant process in copper polishing. During use, the workpiece should be soaked in the drugs and shaken slightly so that the workpiece can have full contact with the drug. Antioxidants have no irritating odor, simple operation, and high production efficiency.

However, after the work parts are treated with pharmaceutical liquid, they must be cleaned with clear water or pure water, otherwise, the work surface will be affected.

The anti-oxidation technical process of crystallizer copper pipe is: deoil → washing 2 → grinding or sulfuric acid activation 10% → washing 2 → anti-oxidation treatment → washing 2 → drying.

Digital continuous casting machine

Breaking through traditional concepts and replacing traditional control ideas with advanced digital technology. Not only does it demonstrate superb process realization capabilities, but also because of the essential changes in its structure, when it achieves effects that traditional systems cannot achieve, there is no need to carry out complex system design, Parameter setting and repeated adjustments will not cause performance changes due to long-term operation.

Therefore, the digital casting machine realizes from the digital liquid level control, digital online width adjustment (slab), digital non-sinusoidal vibration, digital secondary cold water control, digital online soft reduction, etc., in the process of all digitalization of the continuous casting machine, the design is simple, You will appreciate the advantages of high level of technology, low cost and low investment risk.

Hydraulic control continuous casting machine

The hydraulic vibration control system has passed 6 million consecutive vibration tests, and the test data results fully meet the actual production requirements, and the equipment is intact. Because the EMBO digital hydraulic cylinder adopts the international advanced seal structure design, not only will it not cause any leakage, but the life of the seal has also been greatly improved, making the system operating cost far lower than the mechanical vibration system. The friction force of the mold wall against the moving blank shell is considered to be the basic factor that tears the blank shell and limits the casting speed. There is a liquid slag film between the green shell and the mold wall, where the friction is viscous friction, that is, the friction force is proportional to the relative movement speed, and the slag film viscosity is inversely proportional to the slag film thickness. In this way, this frictional force and the tensile stress on the green shell caused by the vibration of the mold are relatively large, and the primary green shell may be cracked. For this reason, non-sinusoidal vibration technology has been developed to reduce this friction. Theoretical research and simulation experiments show that proper selection of non-sinusoidal vibration parameters (deflection rate) can reduce friction by 50% to 60%. Yimeibo Technology has achieved 400 hydraulic vibrations through simple transformation of ordinary continuous casting machines, with a deflection rate of 50%, and it can be adjusted online. It is a new technology to achieve high-quality, high-yield continuous casting machine transformation.

Digital system continuous casting machine

With the dynamic soft reduction process, the continuous caster can control the final solidification stage to avoid the loose center of the slab and minimize the segregation. Dynamic soft reduction can produce slabs with the best inherent quality. As the principle of thin slab direct rolling strip steel continues to be successfully practiced around the world, steel companies that produce high-quality products have begun to generally adopt soft reduction control technology.

Digital slab mold online width adjustment control system. Avoid frequent replacement of the crystallizer, improve the operating rate of the continuous casting machine, and meet the needs of users with multiple specifications and small batches.

The second cold water control system of the digital continuous casting machine crystallizer. The use of digital regulating valve and direct control by PLC avoids the vibration and corresponding lag that are prone to electric servo valves and pneumatic membrane valves, and accurately realizes the dynamic control of the secondary cold water.

For continuous casting machine water cooling, it is mainly composed of rotary joints, water pipes, water pumps, and sufficient water sources. The water cooling system of the continuous caster mainly cools the billet roller of the continuous caster.

Vertical continuous casting machine

The vertical continuous caster was the main model before the 1950s and 1960s. The molten steel pouring system, mold, cutting device, and billet outlet position of this continuous caster are all arranged on the vertical axis of the continuous caster, and the entire equipment occupies a large height space in the workshop.

During the production of the vertical continuous casting machine, the cast slab is solidified in the mold and the second cooling section. Due to the vertical arrangement, the non-metallic inclusions in the liquid metal are easy to float up, and the heat dissipation around the cast slab is relatively uniform, and the cast slab is being drawn During the process, it is not affected by other bending forces, and the resulting cast slab is of good quality and is not prone to cracks. Therefore, it is more suitable for the production of alloy steel and other steels that are sensitive to cracks.

However, this kind of continuous caster is too high, the investment in infrastructure and equipment is large, and maintenance is difficult. Because of the high-head casting, the lower section of the cast slab is prone to bulge deformation under the action of the hydrostatic pressure of the molten steel, so it is only suitable for use Production of cast billets with small cross-sections.

Vertical bending continuous casting machine

Vertical bending continuous caster is a transitional model developed on the basis of vertical continuous caster. Its upper part is the same as the vertical continuous casting machine. The difference is: the vertical bending continuous casting machine uses the top bending device to bend the casting billet by 90° after it is completely solidified, so that the casting billet is tapped and cut in the horizontal direction.

The vertical bending type continuous caster partly reduces the height of the whole machine, but because the cast slab is completely solidified and then top-bent, it is prone to defects such as cracks during production, and is mainly used for the production of small-section billets.

Arc continuous casting machine

The arc continuous casting machine is the most widely used model in the world. Its crystallizer, secondary cooling section, billet straightening machine, etc. are all arranged on a 1/4 circle of the same radius. The cast billet is completely solidified within the 1/4 circle, and the horizontal tangent line must be straightened by a point and then be horizontal. Pull out in the direction, and then cut to length.

1. Full arc continuous casting machine

The full arc continuous casting machine is also called the single point straightening arc continuous windlass. The secondary cooling device of the mold of the full-arc continuous casting machine and the tension-straightening equipment are all arranged on a circle of 1/4 arc. The casting billet forms an arc in the mold, and moves along the arc track after being pulled out, and is cooled by spraying water until it is completely solidified. The fully solidified slab is straightened at the horizontal tangent point, then it is pulled out of the continuous casting machine and cut to length, and then output from the horizontal direction. The height of the continuous caster is basically equal to the radius of the arc. Usually the outer arc radius of the continuous casting machine is called the arc radius of the arc continuous casting machine.

Main advantage

- Because it is arranged in the 1/4 arc range, its height is lower than that of the vertical type and the vertical bending type, the equipment is lighter, the investment cost is lower, and the equipment is easy to install and maintain, so it is widely used;

- Due to the low height of the equipment, the slab bears relatively small hydrostatic pressure during the solidification process, which can reduce internal cracks and segregation caused by bulging deformation, which is beneficial to increase the drawing speed and improve the quality of the slab.

Main disadvantage

- During the solidification process of molten steel, non-metallic inclusions tend to accumulate in the inner arc, which is easy to cause the defect that the inclusions on the inner arc side of the cast slab are enriched at about 1/4;

- In order to prevent internal cracks, the billet is required to be completely solidified before straightening, which limits the increase in the drawing speed and affects the production capacity.

2. Multi-point straightening arc continuous casting machine

As the casting speed of the continuous caster increases, the slab cannot be completely solidified when it reaches the straightening point. When the slab with a liquid core is subjected to single-point straightening, due to the large deformation of the solid-liquid interface, cracks are likely to occur in the center of the slab defect.

Therefore, the multi-point straightening technology is used to disperse the total strain into the strain of each straightening point, so that the deformation rate of the solid-liquid interface of the slab is reduced. In this way, the cast blank can be straightened with a liquid core without internal cracks, which is beneficial to increase the drawing speed.

3. Straight crystallizer arc continuous casting machine

Straight mold arc continuous casting machine (straight arc continuous casting machine) adopts straight mold, the mold is equipped with a linear section of 2.5~3.5m down, and the casting billet with liquid core is gradually bent after passing through the linear section. In an arc shape, the subsequent process is exactly the same as that of a multi-point straightening arc continuous casting machine.

Main advantage

- Retaining the advantages of the vertical continuous caster, the molten steel in the straight mold and its lower straight section during the solidification process is conducive to the floating and uniform distribution of large inclusions in the molten steel. It avoids the defect of inclusions enrichment at 1/4 of the inner arc side of the cast slab, and has a significant effect on the production of high-clean steel;

- Since the casting slab is gradually bent into an arc with a liquid core, it still has the advantages of lower equipment height and lower construction cost of the arc continuous casting machine.

Main disadvantage

The straight arc continuous casting machine has one more bending process, which increases the possibility of cracks on the outer arc side for crack-sensitive steels.

It should be said that the straight mold arc continuous casting machine is a new type of continuous casting machine that integrates the advantages of vertical and arc continuous casting machines. At present, more and more steel mills use this type of slab continuous casting machine, because It can better meet the quality requirements of cast slabs and improve production efficiency.

The continuous casting machine (CCM) consists of a molten steel carrier device (ladle, turntable), a tundish and its replacement device, a crystallizer and its vibration device, a clamping roller in the second cold zone and a cooling water system, a straightening machine, a cutting device, a guide Ingot device, etc.).

The tundish plays the role of buffering and purifying molten steel, and its capacity is generally 20% to 40% of the capacity of the ladle. The more the number of casters, the greater its capacity. The mold is the “heart” of the continuous casting machine. It requires good thermal conductivity, structural rigidity, wear resistance, and easy manufacturing and maintenance. It is generally made of forged copper or cast brass, and its outer wall is forced to cool evenly with water. .

The role of the crystallizer vibrating device is to make the mold periodically vibrate to prevent the primary shell and the mold wall from being bonded and broken. The vibration curve generally changes according to the sine law to reduce the impact. Its amplitude and frequency should be consistent with the tension. Fast and close cooperation to ensure the quality and output of the cast slab.

The secondary cooling device is installed next to the exit of the crystallizer, and its function is to accelerate the solidification of the cast slab and control the temperature of the cast slab by means of water spray or atomized cooling.

The nip rollers and guide rollers support the high-temperature cast billet with liquid core to prevent bulge deformation or internal cracking. At the same time, liquid core reduction technology can be used in this section to improve the quality and output of the cast billet. Water in the secondary cooling device is required. The pressure and water volume are adjustable to meet the needs of different steel grades and different drawing speeds.

The function of the stretch straightening machine is to provide the power to draw the billet and to straighten the bent cast billet, and to push the cutting device to move. The billet speed has a great influence on the output and quality of continuous casting. The function of the starter is to continuously Before the casting starts, block the lower mouth of the mold with the pilot ingot head, and after the molten steel is solidified, pull the casting billet out of the casting machine, then disengage the pilot ingot head, and put the pilot ingot rod into the storage device.

The slab cutting equipment cuts the slab in continuous motion to a fixed length. Commonly used cutting equipments include flame cutters or hydraulic shears and swing shears.

The production process of continuously casting high-temperature molten steel into a slab with a certain cross-sectional shape and a certain size is called continuous steel casting.

The equipment required to complete this process is called a complete set of continuous casting equipment. The electro-hydraulic integration of steel casting equipment, continuous casting machine body equipment, cutting area equipment, ingot bar collection and conveying equipment constitutes the core part of continuous steel casting equipment, which is customarily called continuous casting machine (CCM).

Introduction of continuous casting machine

Continuous casting machine production process. The high-temperature molten steel is continuously poured into one or a group of water-cooled copper molds, and the molten steel gradually solidifies into a billet shell along the periphery of the mold. When the steel liquid level rises to a certain height, the billet shell is solidified to a certain thickness, and the tension leveler will The billet is drawn out, and the cast billet is completely solidified by spraying water in the secondary cooling zone, and is cut to length by the cutting device according to the rolling requirements.

This process of directly pouring high-temperature molten steel into steel billets is called continuous casting. Its appearance has fundamentally changed the steel ingot rolling process that has been dominant for a century. As it simplifies the production process, improves the production efficiency and the metal yield, saves energy consumption, greatly reduces the production cost, and the advantages of good steel billet quality have been rapidly developed.

For current steelmaking enterprises, whether it is long-process steel-making or short-process steel-making, the equipment of continuous casters has almost become inevitable.

Types of continuous casting machine

Continuous casting machines can be classified in various forms.

According to the structure and shape, the continuous casting machine can be divided into vertical continuous casting machine, vertical bending continuous casting machine, arc continuous casting machine with straight section, arc continuous casting machine, multi-radius elliptical continuous casting machine and horizontal continuous casting machine. With the development of continuous casting technology, research on wheeled continuous casting machines, especially thin slab continuous casting machines, has been carried out.

If distinguished according to the size and shape of the section cast by the continuous casting machine, the continuous casting machine can be divided into slab continuous casting machine, billet continuous casting machine, bloom continuous casting machine, round billet continuous casting machine, and special-shaped section.

Continuous casting machine and thin slab continuous casting machine. The billet continuous caster also includes the rectangular billet continuous caster. Usually, the cast slab with the casting section or equivalent section area greater than 200×200mm is called the bloom, and the cast slab with the section or equivalent section area less than 160×160mm is called the billet. A rectangular blank with a width-to-thickness ratio greater than 3 is called a slab.

If it is distinguished by the number of slab streams that the continuous casting machine can cast under the same ladle, it can be divided into single-strand, double-strand or multi-strand continuous casters.

The crystallizer is a very important part of the continuous casting machine(CCM), and it is a forced water-cooled bottomless steel ingot mold. We can call it the “heart” of continuous casting machine.

Definition of crystallizer

A trough-shaped container with a jacket on the wall or a serpentine tube in the container for heating or cooling the solution in the trough. The crystallization tank can be used as an evaporative crystallizer or a cooling crystallizer. In order to increase the intensity of crystal production, a stirrer can be added to the tank. The crystallization tank can be used for continuous operation or batch operation. The crystals obtained by intermittent operation are relatively large, but the crystals are easy to connect into crystal clusters, which entrain the mother liquor, which affects the purity of the product.

This kind of crystallizer has simple structure and low production intensity, and is suitable for the production of small batch products (such as chemical reagents and biochemical reagents, etc.).

At this time, the inner wall of the mold bears the combined effect of mechanical stress and thermal stress generated by the static pressure of the high-temperature molten steel and the friction force relative to the billet shell, and its working conditions are extremely harsh.

In order to obtain qualified cast steel billets, the basic conditions that the mold should meet are:

- It has good thermal conductivity, so that the molten steel can be quickly condensed and formed.

- It has good wear resistance to extend the life of the crystallizer, reduce the maintenance workload and the time of replacing the crystallizer, and improve the operating rate of the continuous casting machine.

- It has sufficient rigidity, especially in the case of chilling and heating, and a large temperature gradient. Small deformation is required.

- The structure is simple, compact, easy to manufacture, easy to disassemble and assemble, and easy to adjust. The cooling water circuit can be connected by itself for quick replacement; the self-weight is small to reduce the inertial force of the mold vibration and reduce the driving power of the vibration device, and make The crystallizer vibrates smoothly.

The role of crystallizer

- Gradually solidify the molten steel into a blank shell of the required specification and shape;

- Through the vibration of the mold, the billet shell can be separated from the mold wall without being broken or broken;

- By adjusting the parameters of the mold, the casting billet does not produce defects such as squaring, bulging and cracks;

- Ensure the uniform and stable generation of the blank shell.

Type of crystallizer

According to the shape of its inner wall, the type of mold can be divided into straight shape and arc shape.

Straight crystallizer

The inner wall of the straight mold is vertical along the moving direction of the blank shell, so the thermal conductivity is good, and the blank shell is cooled uniformly.

This type of mold is also beneficial to improve the quality of the billet shell and the drawing speed, simple structure, easy to manufacture, easy to install and debug; the inclusions are evenly distributed; but the cast billet is prone to bending cracks, and the height and investment of the continuous caster increase . Straight molds are used for vertical and vertical bending and straight-arc continuous casting machines.

Curved crystallizer

The inner wall of the arc mold is arc-shaped along the moving direction of the blank shell, so the cast slab is not easy to produce bending cracks; but the thermal conductivity is worse than that of the straight mold; The arc crystallizer is used on full arc and elliptical continuous casting machines.

According to the method of obtaining the supersaturated state of the solution, it can be divided into an evaporation crystallizer and a cooling crystallizer; according to the flow mode, it can be divided into a mother liquor circulation crystallizer and a crystal slurry (ie a mixture of mother liquor and crystals) circulation crystallizer; according to the operation mode, it can be divided into a continuous crystallizer And batch crystallizer.

Popularly speaking, the continuous casting mold is a cold forming equipment for molten steel. Basically by the frame, water tank and copper plate (back plate and copper plate), adjustment system (adjustment device, reducer, etc.); lubrication system (oil pipe oil circuit), cooling system and spray equipment.

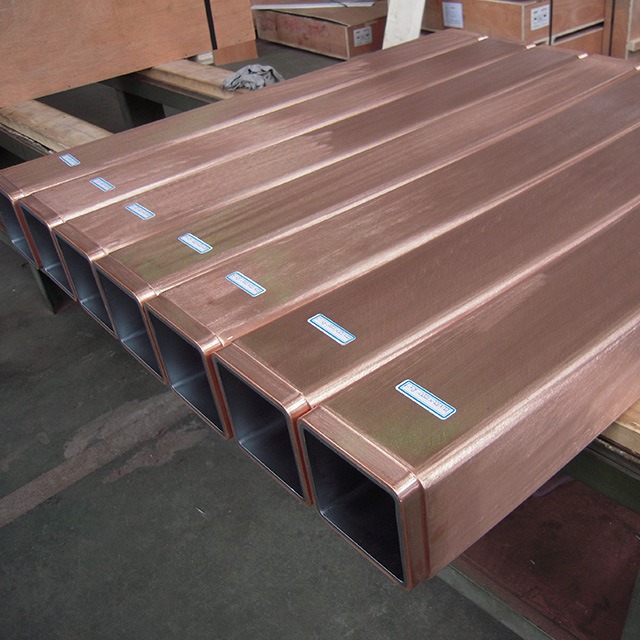

The copper mould tube of the crystallizer of the continuous casting machine is the heart component of the continuous casting machine. During continuous casting, the molten steel passes through the copper tube of the mold to achieve a cooling effect. The molten steel from the mold hardens into a shell.

Due to the current high drawing speed, serious wear on the inner wall of the copper tube. When there is no coating, the bare copper matrix will affect the quality of the billet and even fall off. Therefore, the inner wall of the mold copper tube is required to have a high-quality coating. In the original process, a layer of chromium is electroplated on the inner wall of the copper tube. Because the thermal expansion coefficient of chromium is too different from that of copper, the chromium layer will fall off due to the heat of the copper tube during use. After the layers fall off, the desired effect cannot be achieved. The amount of steel passing is about 4000 tons at most.

According to the electroplating workers, the use environment of the copper pipe adopts a process of first plating a layer of nickel-cobalt alloy and then chromium plating, referred to as composite copper plating pipe. The nickel-cobalt alloy electroplating process can solve the problem of the chromium layer falling off, and at the same time, it has a good bonding force with the substrate. Since the thermal expansion coefficient of the nickel-cobalt alloy is between copper and chromium, it serves as a buffer.

At the same time, in nickel-cobalt alloys, cobalt is resistant to high temperature and wear. Even if the chromium layer falls off, the steel can be pulled. In addition, when the nickel-cobalt alloy is around 500°, it transforms into a magnetic coating, which increases wear resistance. Therefore, the amount of steel passing has increased significantly, and the amount of steel passing is generally around 6000 tons. 2000 tons more than a single chromium layer.

In order to completely solve the peeling off of the electroplating layer of the copper tube of the continuous casting mold, the world’s latest technology is used to electrodeposit the nickel-cobalt-iron plating layer instead of chromium. The steel capacity can reach 10,000 tons.