What is Copper Mould Tube?

Copper Mould Tubes are the most essential part of a Continuous Casting Machine. These help in solidifying Liquid Metal in Continuous Casting Machine for producing Steel Billets. Copper Moulds are situated in the heart of a continuous casting machine. Mould requires extreme high thermal conductivity and high strength. The molten steel will be formed into a certain shaped steel billet immediately after it passes through the copper tube.

Our Products

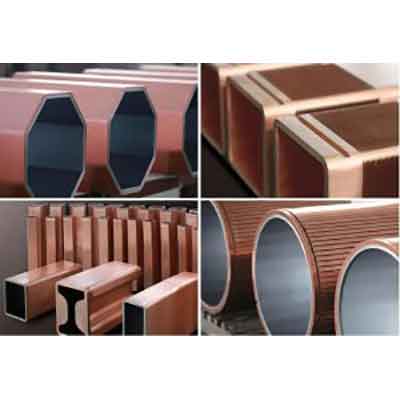

Our products including square / rectangular copper mould tube, round copper mould tube, beam blank copper mould tubes and other non-standard copper mould tubes.

- Upgrade Cuag Material High Quality Copper Mould Tube for CCMAlbert2021-08-09T10:12:31+00:00

Upgrade Cuag Material High Quality Copper Mould Tube for CCM

- Steel Plant Slab Mold Billet Mold Crystallizer Copper Tube for CCMAlbert2022-03-15T03:12:25+00:00

Steel Plant Slab Mold Billet Mold Crystallizer Copper Tube for CCM

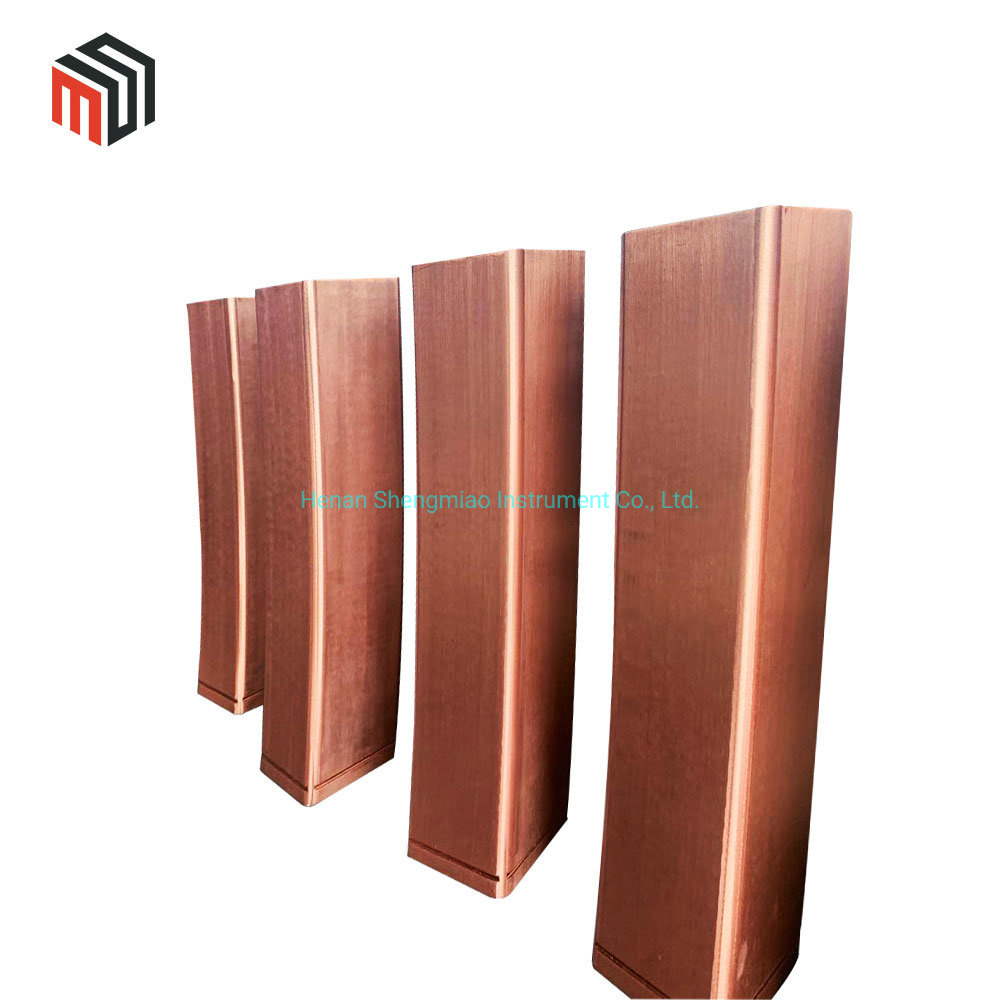

- Square Copper Mould Tube for Continuous Casting Machine for SaleAlbert2021-07-30T08:27:53+00:00

Square Copper Mould Tube for Continuous Casting Machine for Sale

- Square and Retangular Copper Mould Tubes for CCMAlbert2021-07-30T09:13:37+00:00

Square and Retangular Copper Mould Tubes for CCM

- Round Copper Mould Tube for Continuous Casting Machine Use with Different Size for ChoiceAlbert2021-08-09T10:03:22+00:00

Round Copper Mould Tube for Continuous Casting Machine Use with Different Size for Choice

- Round Copper Mould Tube for CCM in Steel IndustryAlbert2021-05-10T02:28:35+00:00

Round Copper Mould Tube for CCM in Steel Industry

Features of Shengmiao Mould Tubes

Chrome Coatting

Chrome plating is furnished to the inside wall of the copper mould tube so as to increase the wear resistance and improve the service life of the tube. Chrome Coating thickness of around 0.10mm is recommended.

Taper

The Taper of Copper Moulds is of vital importance to performance and life. Ranging from Single Taper, Double Taper, Triple Taper to Multiple Taper we supply all variants. Each mould taper is tested by the computer-operated taper monitor and the taper graph for each mould tube is delivered along with mould tubes.

More Other Features

- High casting speed

- Uniform shell growth

- No sticking

- Optimum billet quality

- Longer lifetime and reduced maintenance costs

Benefits of Shengmiao Mould Tubes

Working with Shengmiao means you will get exactly what you desire:

- Reduction of production costs

- Improvement in the quality of your steel

- Trouble-free existence