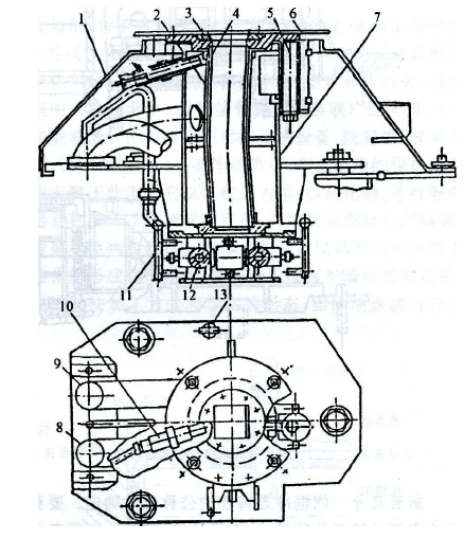

1-Cover 2-Inner Water jacket 3-Lubricating oil cover 4-Inner copper pipe 5-Radioactive source container

6-Cover plate 7-Outer water jacket 8-Inlet pipe 9-Return pipe 10-Receiver 11-Water ring 12-foot roller 13-positioning pin

The Copper mold tube assembly is composed of the following parts: mold copper tube,water jacket, upper and lower sealing flanges, sealing rings, foot roller device, spray device. Among them, the mold copper tube is the core part, and other parts are assembled around the copper tube.

- The mold copper tube is made of copper alloy, and the length is 700-1000mm. If the copper tube is short and the drawing speed is high, breakout is likely to occur; if the copper tube is too long, it will increase the drawing resistance and cause transverse cracking of the cast slab.

- There is a water gap between water jacket and mold copper tube, the size and accuracy of which affect the quality of the cast slab. Generally, the size of the water gap is 4mm, and the accuracy is ±0.2mm.

- Foot roller device

The foot roller device at the lower part of the crystallizer has two functions. One is to guide the head of the starter to prevent the copper tube from being scratched when threading the starter ingot; the second is to hold the billet that has just exited the mold and correct the billet which has little Off-square.

- Spray device

The spray device usually uses 2 to 3 rows of flat nozzles: the blank shell just out of the mold is relatively thin (about 10mm), weak cooling may cause steel breakout, and too strong cooling may sometimes cause defects such as internal cracks; if the cooling distribution is not distributed Even, it is easy to produce defects such as missing squares, dents, and longitudinal cracks.

- Sealing of the crystallizer

Since there is a water pressure of 0.7 to 1.2 MPa inside the crystallizer, the rationality of the sealing structure is very important to the safety of the crystallizer in use and to ensure smooth production. The sealing of the crystallizer mainly refers to the sealing of the upper and lower end flanges of the copper pipe and the sealing of the inner and outer water jackets.