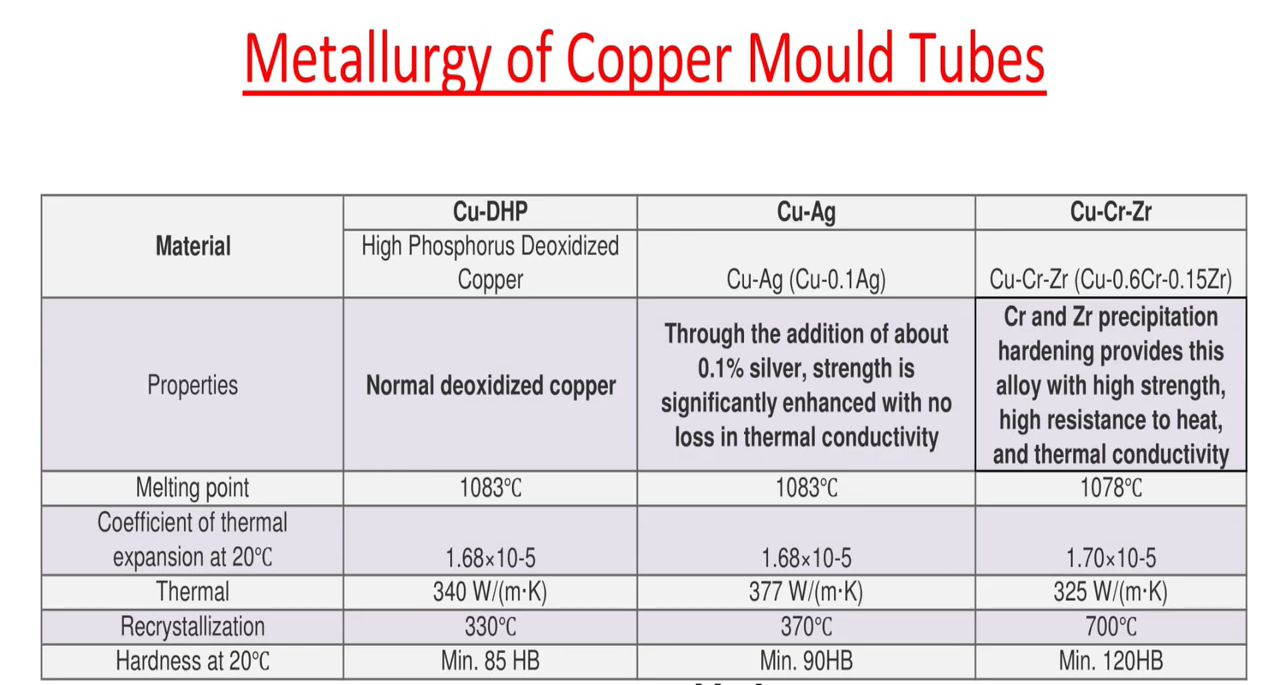

TP2 is a kind of material is selected by most of the steel plants. It shows excellent heat-proof and anti-fatigue property under high temperature and it has good processing property.

CuAg0.1 with 0.08%-0.12% silver during copper ingots melting will increase the recrystallization temperature of copper by 100℃,which will increase the heat stress and anti-abrasive property of copper mould tube interior surface, showing better heat resistant property than TP2.

Cu-Cr-Zr is a kind of copper alloys which can be normalized by time. lt has excellent mechanical property under both room temperature and high temperature. It has high heat conductivity,melting point ,anti-fatigue and anti heat stress properties. Their outstanding features make it different from the previous copper alloys. It combines all good properties together. But compared with other copper alloys, Cu-Cr-Zr is difficult to be formed with higher products costs.